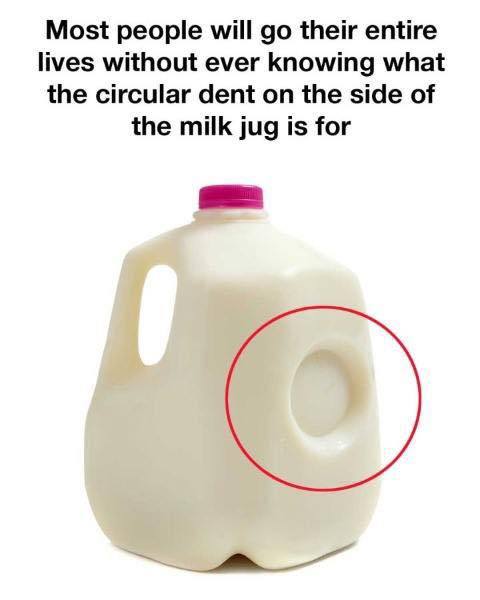

Reducing Plastic Use and Environmental Impact

From a manufacturing perspective, the dent plays a role in material efficiency.

Because it strengthens the jug:

Less plastic is needed overall

The jug remains lightweight

Production costs and environmental impact are reduced

This small indentation helps millions of milk jugs be produced more sustainably every year.

Why It’s Circular, Not Square

The circular shape isn’t random. Circles distribute stress more evenly than corners or straight lines. That’s why engineers prefer circular designs when dealing with pressure and impact.

A round flex panel:

Prevents weak stress points

Improves durability

Responds smoothly to pressure changes

It’s the same reason manhole covers and pressure valves are often round.

A Small Detail With a Big Purpose

The circular dent on a milk jug is a perfect example of invisible design—a feature that works so well you never notice it. It protects against spills, saves material, adapts to pressure changes, and even offers clues about spoilage, all without adding complexity.

So the next time you pour a glass of milk, take a second look at that little circle on the side of the jug. It’s quietly doing a lot more work than most people will ever realize.